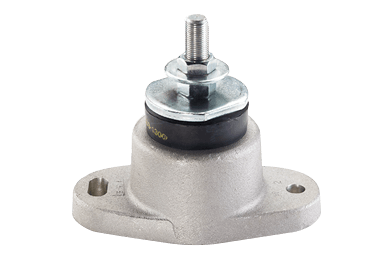

The MB Series are elastomer shock and vibration isolators used under HVAC, power generation and electrical equipment where a seismic design is required. At maximum rated load, the natural frequency range of 12 to 15 Hz offers excellent isolation of structure-borne noise.

The MB Series are also furnished as a complete assembly and feature a built-in leveling device for simple installation. The MB1 and MB3 housings are made of heat-treated cast aluminum, while the MB5 is manufactured from welded steel. All hardware consists of zinc-plated, carbon steel for superior strength and long-life.

The elastomer element resists oils, ozone and most solvents – providing optimum resilience in even the harshest environments. the MB Series works well in mechanical equipment rooms or on outdoor equipment platforms. The operating temperature of -20°F to +180°F offers continuous operation in ambient conditions.

Features & Benefits

- Static load range from 30 to 1300 lbs. offers a wide range of application flexibility

- Cast aluminum housing and carbon steel hardware provide durability in harsh environmental conditions

- Natural frequency of 12 to 15 Hz at maximum load provides structure-borne noise attenuation in even the most challenging applications

- Designed for seismic applications

- Isolator shipped as a complete assembly for ease of installation

- Built-in leveling device offers simplified equipment installation

- Available with longer bolt for height adjustable installation

Applications

- Air handling units

- Fans

- Pumps

- Chillers

- Air compressors

- HVAC equipment

- Power generation

- Electrical transformers

- Motors