Heavy Duty Slewing Rings, Turntable Bearings, & Slewing Drives

February 18th, 2025 by David Casillo. Product NewsSlewing Rings / Turntable Bearings / Slewing Drives

For Heavy-Duty Applications

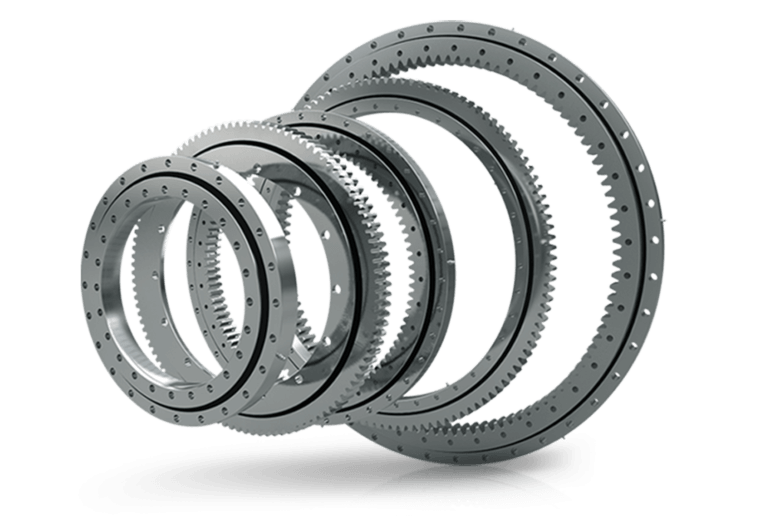

The rugged ball-bearing and crossed roller slewing rings from Isotech are characterized by their large diameter and large bores with only a small cross-section. They were designed for axial, radial as well as combined axial and radial loads. New design concepts and improved manufacturing processes for the ball-bearing and crossed roller slewing rings, enable our customer’s designers to implement completely new solution approaches.

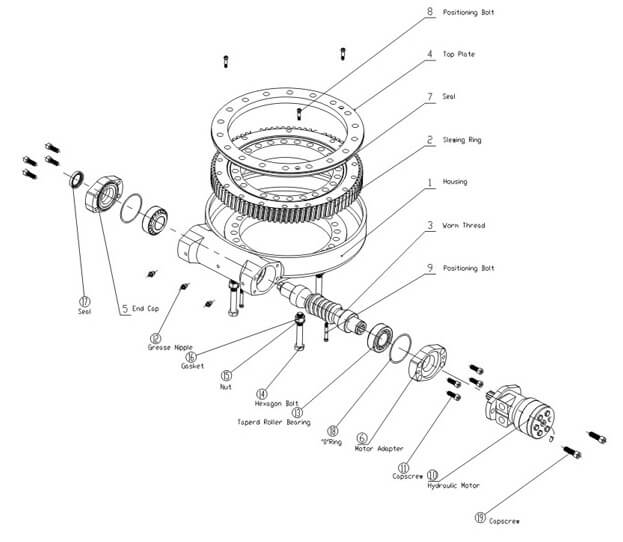

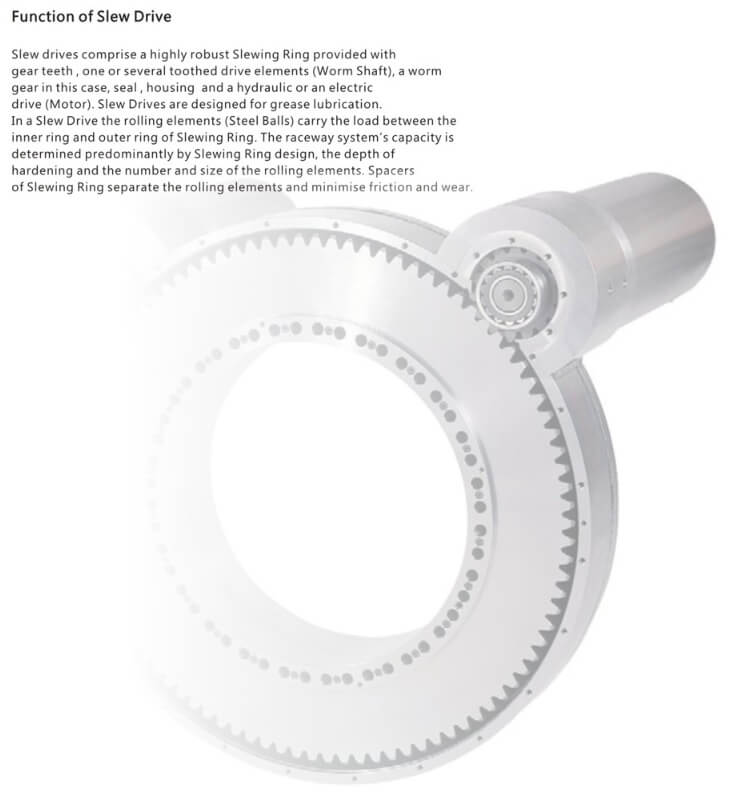

Slew Drives

Slew drives are an all-in-one unit comprised of geared slew ring, drive gear, housing, and motor (electric or hydraulic). Designed for axial, radial, and moment loading.

Slew Drives are powered with hour glass (Double Enveloping) worm technology for increased load handling, efficiency and accuracy.

We manufacture a wide variety of drive styles, model sizes, performance ranges, sealing options, and mounting characteristics.

Standard model sizes from 75mm to 800mm in diameter.

Performance load characteristics range from:

– 6kNm to 220kNm holding torque

– 200Nm to 63kNm output torque

– 500Nm to 271kNm overturning moment load capacity

Gear reduction ratio 30:1 to 156,600:1

Horizontal, vertical, or combination of multiple axis mounting

Single or Dual drive

Electric or Hydraulic motor option

Housing: Open or Closed

Customized input configurations

Custom designs per application requirements

Applications:

Agricultural machinery

Conveyors

Cranes & derricks

Excavators

Indexed, positional, and rotating tables

Industrial robots

Lifts

Medical scanners & imagers

Mining equipment

Rotating displays

Satellite & radar antennas

Solar panels

Textile looms

Vehicle trailers

Wind & underwater turbines

Categories

Keywords

Copyright© 2025 Isotech, Inc. All rights reserved.