Click to request more information

Since 1983, Isotech, Inc. has collaborated with customers in the aviation and aerospace,

transportation, off-highway, marine and medical industries to design and engineer industry-leading

acoustic and thermal control products. Isotech’s comprehensive approach to acoustic and thermal

management from problem diagnosis, to product engineering to production and ongoing quality has

positioned the company as a premier supplier of foam technology around the world. A

broad range of in-house capabilities ensure products are available with or without adhesive, laminated,

coated or embossed, cut to size or delivered in sheets, rolls or buns to meet the exact specifications of

each customer.

ABSORPTION PRODUCTS

All materials are available in sheets, die-cut parts or kits with high performance pressure

sensitive adhesive for easy installation. Embossing is available. Parts can be unisealed for

added durability on all faces and edges.

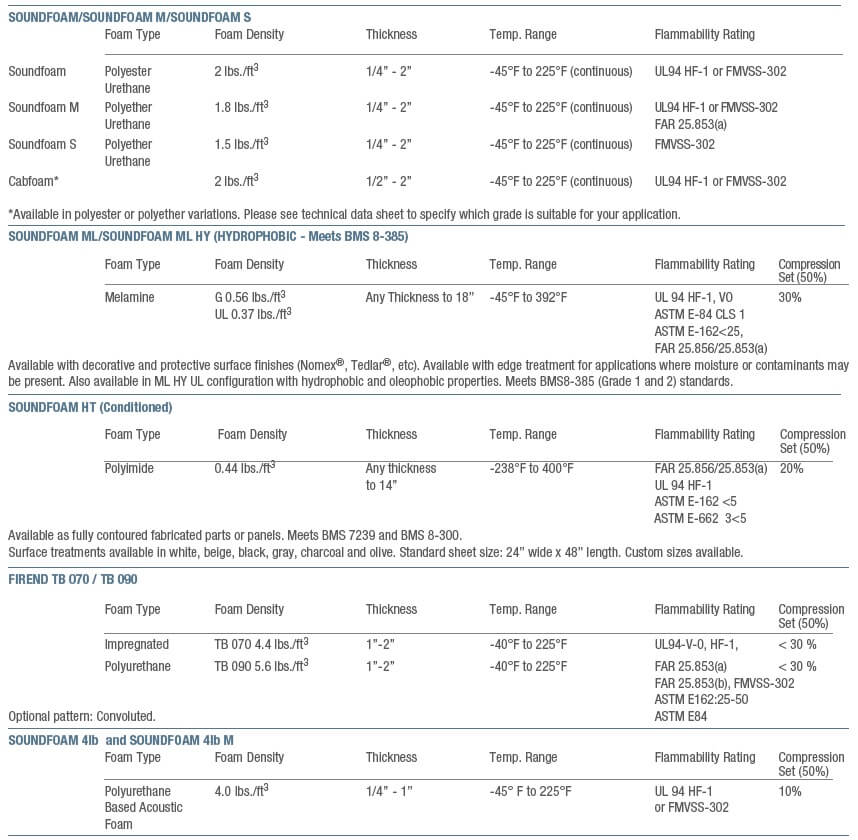

Soundfoam / Soundfoam M / Soundfoam S

SOUNDFOAM:

• Polyester based urethane foam

• Homogenous structure resists degradation

• Ideal for electronic equipment, medical, and appliance applications

SOUNDFOAM M:

• Polyether based urethane foam

• Excellent hydrolytic stability for moisture and humidity

• Ideal for off-highway, construction, agricultural equipment, HVAC, marine,

and power generation

SOUNDFOAM S:

• Polyether based urethane foam

• Ideal for the transportation industry

CABFOAM:

• An acoustic quality, flexible, open cell polyurethane foam, having

an exclusive honeycomb pattern and a tough polymer finish

All foams designed to provide maximum sound absorption over a wide frequency range in minimum thickness.

Wide selection of film facings, styles, optional coverings and patterns.

Uniseal option available for maximum protection of facing and edges.

Soundfoam ML/Soundfoam ML HY

• Lightweight, flexible melamine foam

• Excellent heat resistance; excellent flammability resistance

• Ideal for acoustic or thermal insulation on vehicles, electronic equipment, aircraft,

building construction

• Soundfoam ML HY is treated to be both water and oil repellant – meets BMS 8-385

• Available in sheets, rolls, blocks, die-cut, water jet cut or contour cut parts

• Available in ultra light (UL) weights with hydrophobic and oleophobic properties

• Soundfoam ML HY ULb is Boeing approved for BMS 8-385 Type 1, Grade 2,

Soundfoam ML HY ULb PE4 is approved for Type 6, Grade 2 and Soundfoam

ML HY ULb PE5 is approved for Type 6, Grade 2

• Soundfoam ML HY G is Boeing approved for BMS 8-385 Type 1, Grade 1

and Soundfoam ML HY G TD4 is approved for Type 4, Grade 1

Soundfoam HT (Conditioned)

• Very lightweight polyimide foam

• Provides excellent sound absorption as well as thermal insulation

• Excellent cohesive strength, low outgassing properties

• Will not mold, rot, or erode due to vibration

• Fire resistant; preferred sound absorption material for fire safety areas

• Stable over extreme temperatures

• Ideal for aerospace, marine, military – commercial aircraft and electronics

• Patented Soundcoat conditioning process improves acoustic absorption and

foam modulus properties

FIREND TB 070/TB 090

• Carbon impregnated polyurethane foam formulated for maximum fire protection

• Maintains fire ratings with a variety of protective films and facings

• Excellent absorption and thermal insulating properties

Soundfoam 4lb/Soundfoam 4lb M

• Open cell, flexible polyester or polyether based urethane foam

• Designed to provide maximum sound absorption in minimum thickness

• Excellent heat, humidity, flame, and chemical resistance

• Available with various protective and decorative surface finishes

All materials available in sheets, die cut parts, and kits with high performance pressure sensitive adhesive for easy installation

ABSORPTION PRODUCT INFORMATION

Click to request more information

Categories

Keywords

Copyright© 2025 Isotech, Inc. All rights reserved.